Our silicone heating systems revolutionize agricultural drying processes by combining flexible heating technology with aluminum-enhanced thermal management. These integrated solutions deliver gentle, controlled heat perfect for preserving the quality of temperature-sensitive crops like tea leaves, medicinal herbs, and specialty produce.

Key Features of Our Silicone Heating Technology

Agricultural drying demands gentle yet precise thermal control to preserve crop quality. Our silicone heating technology meets these challenges through innovative engineering that outperforms conventional drying methods. Here's what makes it exceptional:

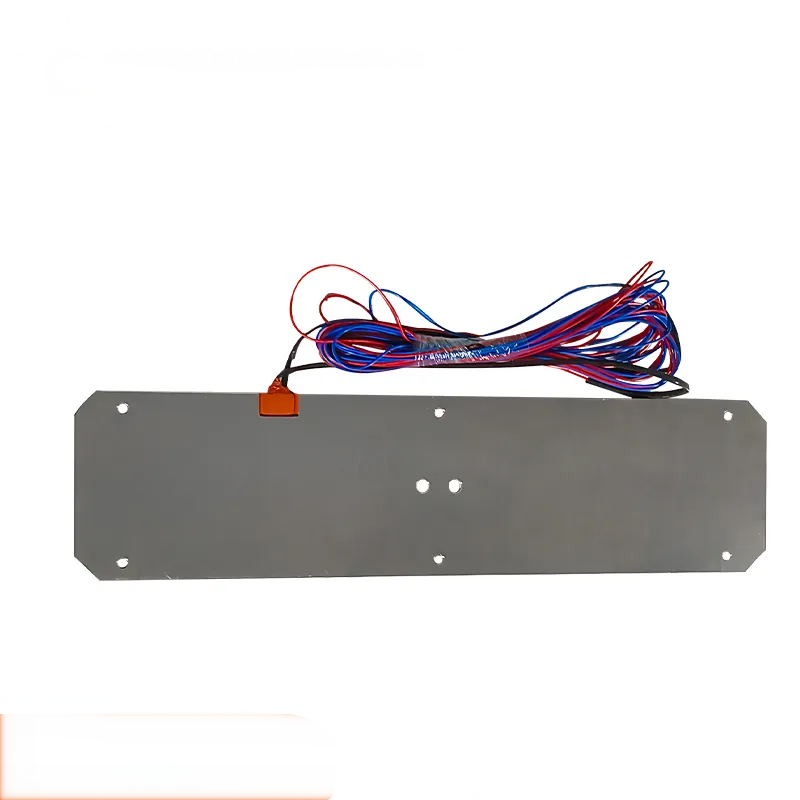

1. Flexible yet Durable Construction: The silicone-aluminum composite design provides both the conformability to wrap around drying surfaces and the structural rigidity for long-term use.

2. Precision Temperature Control: Maintains ±1°C uniformity across the entire drying surface

3. Optimized Heat Transfer: Aluminum backing ensures rapid, even heat distribution while preventing hot spots

4. Moisture-Resistant Design: Waterproof construction withstands high-humidity drying environments

How Silicone Heaters Solve Real-World Drying Challenges?

Our silicone heating systems address critical pain points in agricultural drying operations through innovative engineering solutions. The case of the premium tea producer demonstrates how our technology overcomes three major industry challenges:

1. Quality & Speed Unified

Eliminates the trade-off between drying speed and product quality, preserving 98% of delicate aromas while processing crops 20% faster than conventional methods

2. Smart Energy Use

Reduces power consumption by 25% through optimized heat transfer, cutting operational costs without compromising performance

3. Precision Adaptability

Customizable temperature profiles (40-60°C) accommodate diverse crops - from delicate white tea to robust medicinal roots

Why Silicone Heaters Transform Agricultural Drying?

Traditional drying methods sacrifice quality for speed or efficiency. Our silicone heating technology breaks this compromise by delivering gentle yet precise heat that preserves delicate aromas and nutrients while cutting energy use by 25%. The waterproof aluminum design withstands humid conditions, while ±1°C temperature control ensures perfect results for any crop - from delicate teas to medicinal herbs.

For producers, this means higher-quality products that command premium prices, plus lower operating costs that boost profitability. It's not just drying - it's intelligent crop preservation.

Elevación del secado agrícola con soluciones de calentamiento inteligentes

Nuestros sistemas de calefacción de silicona representan un enfoque transformador para el secado agrícola, combinando la ingeniería de precisión con la innovación práctica. Al abordar los desafíos fundamentales de la preservación de la calidad, la eficiencia energética y el control de procesos, esta tecnología permite a los productores alcanzar resultados superiores mientras optimilos costos operacionales.

Los beneficios mensurables — desde una mayor retención de aromas hasta un ahorro significativo de energía — demuestran cómo la gestión térmica inteligente crea valor tangible en todo el sector agrícola. Ya sea procesando delicadas hierbas medicinales, tés de alta calidad o cultivos especiales, nuestroCalentadores de silisiliEntregue el calor suave pero eficiente necesario para una calidad de producto superior.

Ofrecemos una amplia variedad de calentadores de alta eficiencia y elementos calefactores. Tales como calentadores de poliimida /kapton, calentadores de goma de sili, calentadores transparentes de PET, calentadores de película gruesa, calentptc, calentde mica, calentcalentde resina epoxy y película de calentamiento de grafeno.